Purpose-built for production floors that don’t have time for downtime.

Explore our series of System Options to expand your capability and improve efficiency

Eliminate timely changeovers

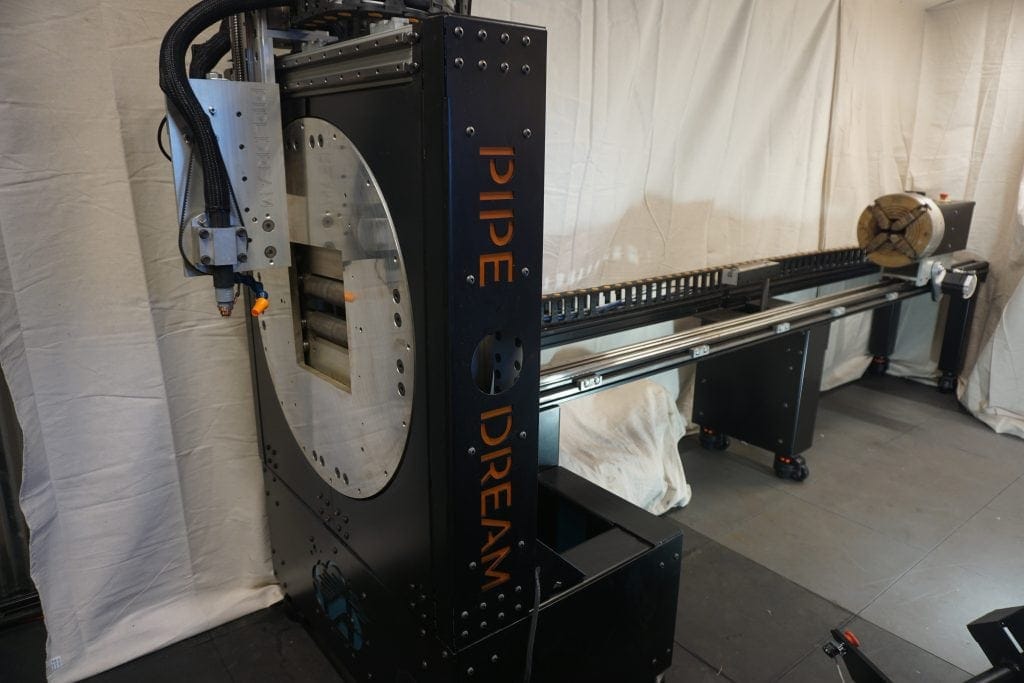

Cuts pipes up to 800 pounds without compromise.

Feature rich and User Friendly Control system-Integrated CAD/CAM/CNC

Don’t take our word for it. See it Live

Our system was designed with an emphasis on optimizing the user experience.

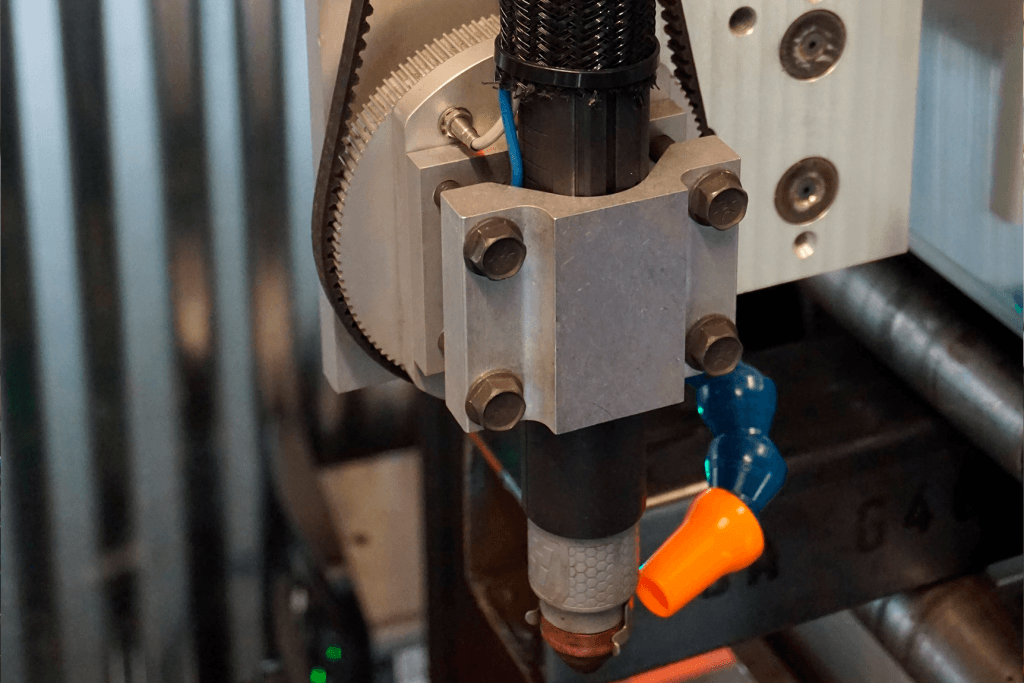

Some of the key features/options that set our system apart include:

Cut customizable profiles with just a few clicks.

Industrial-grade performance.

Bevel, Engraving, Laser Alignment, Material Lifter, Laser Alignment, Fume Extraction, and More

Common Questions About the PD-10

Most shops train operators in under a day—thanks to intuitive FlashCut software.

Cuts round, square, and rectangular tubing (up to 10” x 10” and 800 lbs.). And flat material up to 10” wide.

Yes—engineers provide remote or in-person setup assistance.

Need Answers Fast?

Phone Support: